Safety underway

On the road in times of acute viral infection risk

Please note that the claims being made in the following communication only apply to European countries. For locations outside of the European Economic Area (EEA) you should first review local regulatory restrictions. For the USA, the product is not available until the pending registration with the United States Environmental Protection Agency (US EPA) has been completed.

As the coronavirus pandemic continues to intensify, the need to protect ourselves in all situations is

constantly increasing.

Car travel may not be the obvious place to start. However, traveling with two or more people in the same confined space has increased health risks. In this context, the quality and effectiveness of the vehicle’s cabin air filter plays an important role.

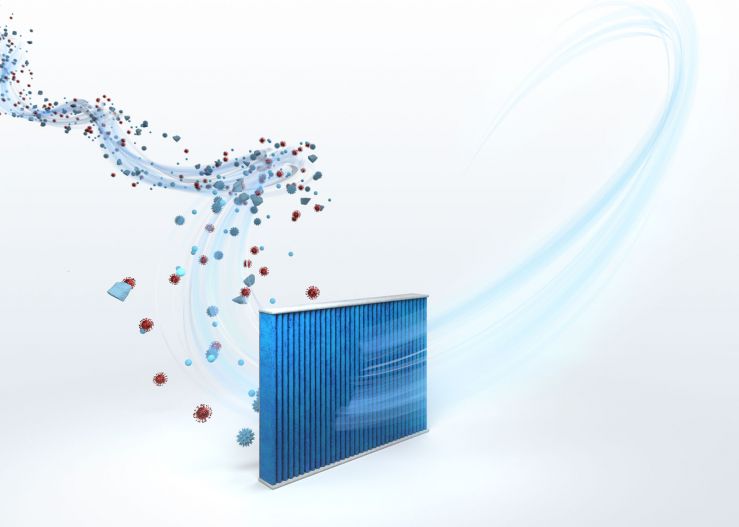

On the one hand, the cabin air filter needs to clean the fresh air entering the cabin as thoroughly as possible, which contains everything from submicron particles to large pollens. At the same time, the circulating air inside the cabin must also be cleaned by high-efficiency filter media. An infected person inside the vehicle, will release viruses simply by breathing or, much more intensively, by coughing or sneezing. These viruses populate the passenger compartment in finely distributed form and can only be diluted either by an increased supply of fresh air or by the cabin air filter cleaning the circulating air.

In terms of guarding against virus infections, cabin air filters perform two functions. First, the elimination of airborne viruses from the airstream via the separation of particles by the filter media. As this traps viruses within its structure, the second function of the filter is the inactivation of the collected viruses.

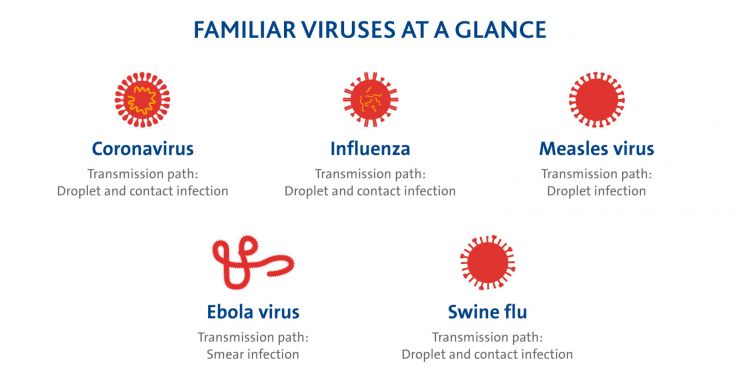

Understanding virus behavior

Airborne viruses are present in droplets (containing a large number of organic particles and viruses 50-200µm) emitted by breathing and, much more intensively, by coughing and sneezing. These liquid droplets of relatively large size (up to 15µm) reduce their diameter within seconds via evaporation. This creates droplet nuclei with very small particle diameters down to 0.1µm.

The tiniest of these virus-bearing droplet nuclei remain suspended in the air for a long time and can easily be inhaled. Droplet nuclei with a particle size down to 0.1µm are the greatest threat to human health, because they can directly enter the lung’s alveoli – in other words, the main battlefield of human immune defense against viruses. Viruses that attach themselves to larger droplets weighing >5µm settle on surfaces and become passive sources of infection, passed on by touch or wiping.

The higher the separation efficiency of cabin air filters, the better the virus separation; this is determined by the type of media used to make the filter. The efficiency range extends from “standard” cabin air filters to the almost HEPA-quality filters found in the most advanced electric vehicles. These separate as much as 99,995% of all relevant particles among viruses, fungal spores and bacteria and offer excellent levels of protection.

Design and materials are crucial

Nevertheless, if the efficiency of the filter medium is maximized, even standard cabin air filters can be very effective in eliminating viruses. An important functional characteristic of high-efficiency cabin air filters is their high filtration efficiency (typically >80%) against typical submicron test aerosols like sodium chloride. Maximizing the long-life separation filtration efficiency of these cabin air filters relies on the quality and composition of the materials used in their design. Ideally, the microfibers or other novel high-performance media employed should have been specifically designed and manufactured for use in cabin air filters. If in doubt as to the vehicle’s current cabin air filter performance, its filter can be easily and quickly upgraded to high-efficiency micronAir cabin air filters.

Inactivating captured viruses

Once the vehicle’s air conditioning system has separated the virus-bearing particles, they need to be rendered harmless. There are typically two basic approaches: heat and pH values. Inactivation via thermal treatment depends on the virus type. In some cases, they can be eliminated at just 35°C (95°F). Other virus types require temperatures up to 70°C (158°F) to make them inactive, which is typically beyond the operating parameters of cabin air filters. Both ends of the pH scale – acid and alkali – effectively kill viruses. We are already familiar with this principle through domestic vinegar- or lemon-based acidic cleaning products or strongly alkaline disinfection agents.

(Image source: OFI)

The power of natural extracts

The micronAir proTect series of cabin air filters use a natural fruit extract to create an acidic environment in the filter material that supports virus inactivation. Even extreme temperature and humidity stresses cannot significantly disrupt the key acidic functionality of micronAir proTect filters. We are currently conducting tests on various viruses in accordance with the internationally established ISO 18184 standard to provide concrete scientific evidence of this. Based on results so far, we expect significant anti-virus effects from these advanced filters.

Freudenberg Filtration Technologies is working closely with two leading international test institutions to achieve third-party validation: the OFI (Austrian Research Institute) in Vienna for microbiological analysis, including filter performance testing, and the Guangzhou Institute of Respiratory Diseases (GZIRD) for antiviral testing.

Although the research remains ongoing, preliminary results have been extremely encouraging. Our collaboration with the GZIRD has established that micronAir proTect cabin air filters demonstrate very high virus inactivation properties. For example, running the ISO 18184 test with micronAir proTect filter media showed virtually a 100% success rate in eliminating the H1N1 and HCoV-229E virus. We expect to receive further results shortly.

Setting new standards of testing

Because our aim is to transfer both the established test procedures and the familiar ISO 18184 test methodology to specific filter applications, these antiviral tests are highly complex and time-consuming. We need to simulate a filter application that is as close as possible to reality by means of airborne bio-aerosols contaminated with viruses.

The decisive factor is the virus concentration found in the clean air that was able to pass through the filter, and the subsequent microbiological evaluation of the activity or inactivity of the viruses. We have already established that pH values <4 and >9 support inactivation. Temperatures above 35°C (95°F) also have a strong inactivation effect. In other words, it can be assumed that the activity of viruses is significantly reduced in summer.

In the short term, while we remain in the grip of the global coronavirus pandemic, one simple and beneficial course of action is to install a micronAir proTect series cabin air filter – equipped with natural fruit extract to actively fight viruses.

Finally, whichever cabin air filter you choose, it is vital to ensure that it is regularly changed – under present conditions, even more often than usual. This is the only way to ensure the optimum level of protection. At the same time, it certainly helps to disinfect the filter installation space with commercially available sprays before installing the new filter.

Further information about all our cabin air filters can be found here

automotive filtration insight

automotive filtration insight