Clean air for fuel cells

Specialized filtration solutions for hydrogen-powered vehicles

If the world is to successfully combat growing levels of air pollution, transportation must shift from its reliance on fossil fuels to alternative energy solutions. Among the various emerging drive technologies, fuel cells are proving an alternative to combustion engines.

Where pure electric vehicles are restricted by their relatively low range and power, fuel cells – especially when used in combination with batteries – can match the power and range of combustion engines, while eliminating their environmental disadvantages.

Chemically pure, environmentally friendly

A fuel cell derives its energy from a chemical reaction, as Project Engineer Tobias Beisel explained: “The cell consists of electrodes separated by a membrane. At the anode, the hydrogen oxidizes and releases electrons and protons. The positively charged protons pass through the membrane, stimulating an electrochemical reaction.” To achieve this, each electrode is covered with a catalyst. The negatively charged electrons flow through an external circuit, generating electricity. To create sufficient energy to drive a vehicle, the cells are connected in stacks. Maximum power output relies on clean air supply.

Fine dust and sulfurous gases reduce power

As a rule, fuel cells use the oxygen in ambient air for their reactions. This air is not clean. Depending on the surroundings, the mix of harmful particles and gases can vary greatly. Major cities are likely to have a different mix of contaminants than smaller cities, whereas in coastal regions salty air can be the largest atmospheric challenge for the fuel cell. Whatever the pollution mix, the charging system draws in large volumes of particles and noxious gases over time. What represents a health problem for humans also has a damaging impact on fuel cells.

The pollution cocktail

While some particles and gases lead to short-term power loss, others can cause irreparable damage to the fuel cell. For example, fine dust affects the function and efficiency of the components and blocks the flow channels of the fuel cell itself. This leads to greater flow resistance and a permanent loss of energy. Salts and harmful gases effectively ‘poison’ both anode and cathode sides of the catalyst and decrease catalytic activity. Sulfurous gases are especially harmful. Even small amounts of sulfur contaminants collecting on the stack components can eventually lead to complete fuel cell failure.

Freudenberg provides the answer

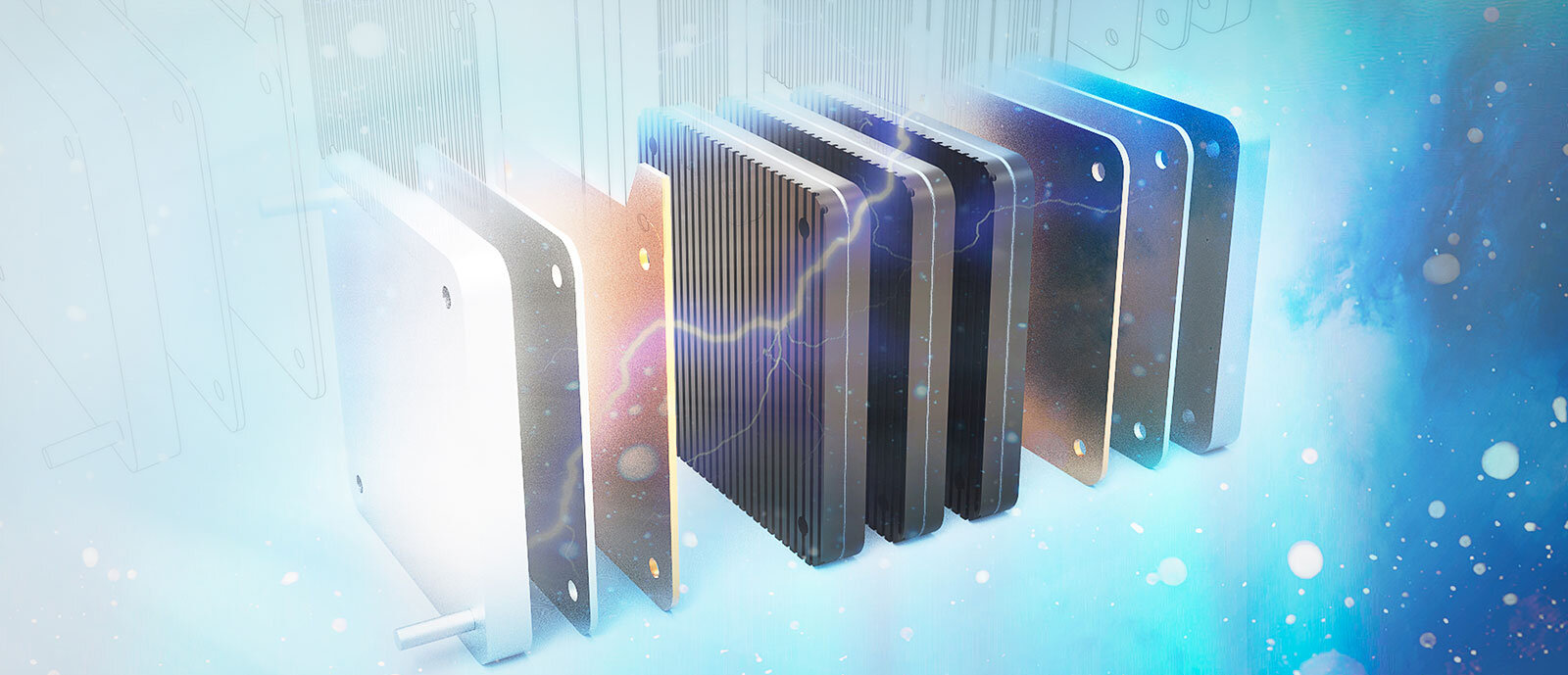

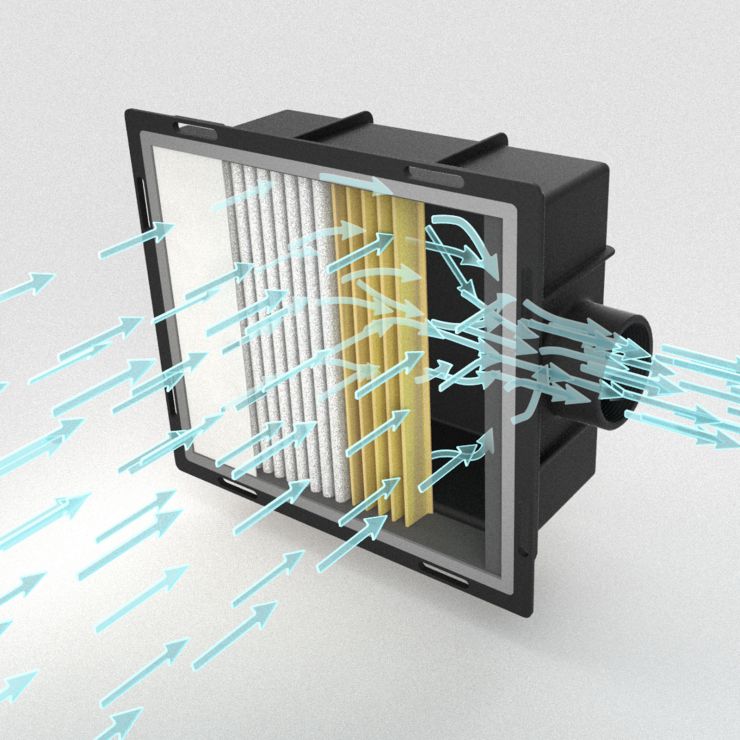

The key to solving the problem of contaminants is to simply prevent them entering the cells in the first place. Simple in principle, but technically complex in practice. Effectively protecting a fuel cell requires a sophisticated combination of particle filter layers and chemical filter layers with specific adsorbent configurations, such as activated carbon. This is where the innovation and technical power of the different specialized business groups of Freudenberg comes into play. Meeting the challenge involves close interaction between several of the 11 business units that Freudenberg is able to deploy.

Innovating together – literally

In the case of the fuel cell stack, solutions from Freudenberg Sealing Technologies ensure that the individual stack layers are sealed to prevent the reactants from leaking out. Freudenberg Performance Materials then supplies gas diffusion layers that optimize the flow of gas within the cell. On the periphery of the fuel cell, humidifiers from Freudenberg Filtration Technologies prevent the delicate membrane in the cell from drying out. At the same time, specially developed filters protect the catalyst material, membranes and system components from contaminant gases and particles.

Size matters

In general terms, the larger the filter the better the pressure drop, efficiency and longevity. However, smaller filters fit more easily into the condensed drive unit compartment and leave room for other components. Ultimately, it is down to the vehicle manufactures to decide what to prioritize and what degree of efficiency and lifetime they want to achieve. Having been involved in fuel cell technology since its earliest days, Freudenberg Filtration Technologies will continue to work in close partnership with OEMs as this alternative fuel solution is explored. Together, we look forward to enabling the next step in environmentally friendly mobility, worldwide.

You can find out more about this cutting-edge topic here

automotive filtration insight

automotive filtration insight