Protecting mass-transport passengers

Safety on the bus thanks to innovative new filtration concept

Please note that the claims being made in the following communication only apply to European countries. For locations outside of the European Economic Area (EEA) you should first review local regulatory restrictions. For the USA, the product is not available until the pending registration with the United States Environmental Protection Agency (US EPA) has been completed

Given the vast numbers of people who use mass transit such as buses and coaches daily, these modes of transport represent an obvious source of viral infection risk. This created an opportunity for Freudenberg to manufacture an innovative filtration solution specifically aimed at these mass-transport vehicles.

The new solution is based on our well-established and highly successful range of premium micronAir blue cabin air filters and can – as part of a comprehensive hygiene concept – remove virtually 100 percent of particles from the air circulating in bus cabins.

Layered protection

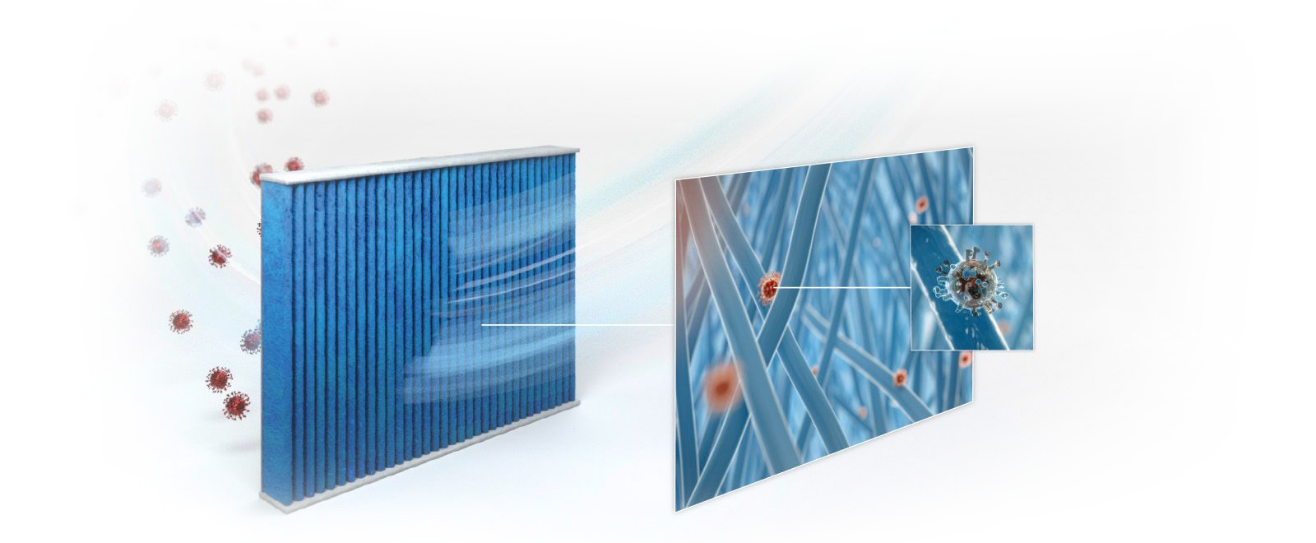

The key to the efficiency of these premium cabin air filters is the engineering construction of up to four separate layers of filtration media: two particle filters, an optional third activated carbon layer that removes harmful gases, and the crucial bio-functional layer impregnated with fruit extract. This anti-viral filter layer adds an effective shield against airborne aerosols that can potentially carry pathogens such as the many different coronaviruses. The new filter solution was developed during a research project initiated by an Austrian coach operator and conducted in close collaboration with the independent research and testing institute OFI and German bus manufacturer EvoBus.

The power of joint innovation

Innovating together with and for our customers is a key driver of innovation at Freudenberg. In this case, the goal was to develop a comprehensive hygiene concept for bus travel.

Application engineer Tobias Beisel

Unique progressive three-stage system

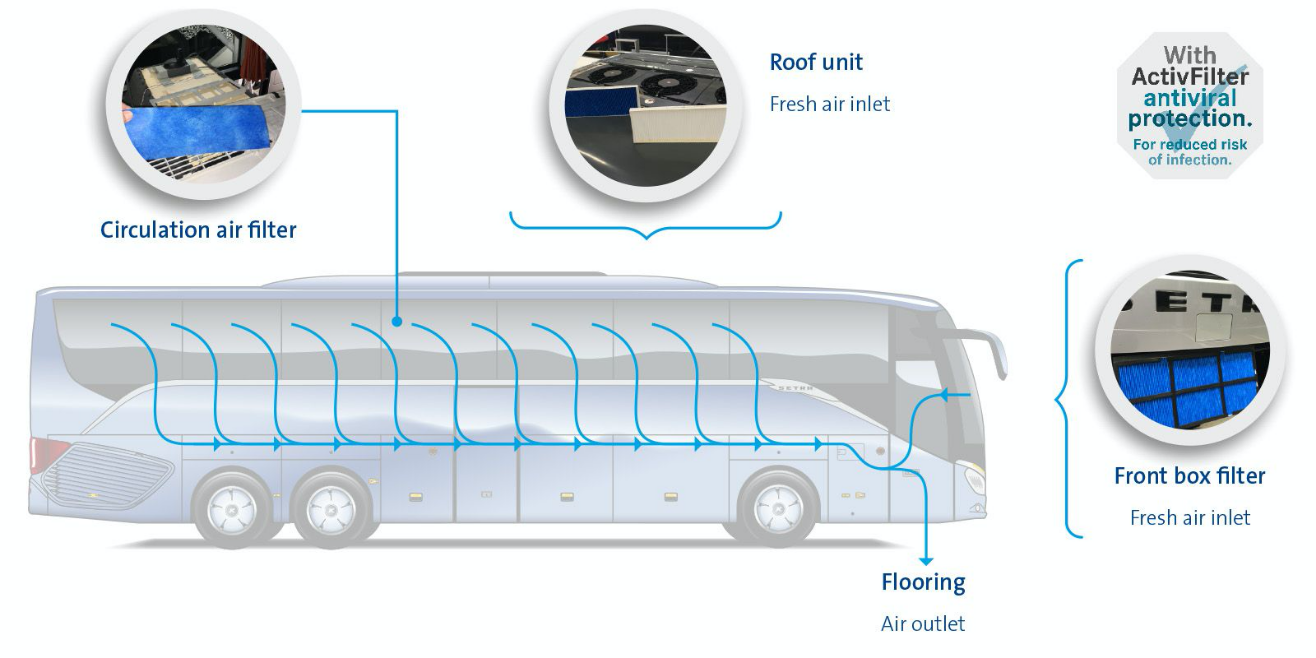

Optimizing air quality on buses is a complex process involving not just filtration, but also the frequency of air exchange, an increased proportion of fresh air and reduced turbulence. Freudenberg’s prototype concept was based on a bus model with three different filters: a front box filter to clean the air for the driver, a recirculation filter mat in the ceiling, and a third filter in the air conditioning unit on top of the bus. Tobias Beisel described the process: “The challenge was to reliably capture particles as small as 0.4 μm as well as tiny aerosols, while keeping the air filter resistance to a minimum to avoid energy efficiency losses. The result was a unique three-stage progressive design in which all filters are carefully aligned with each other.”

Reliable protection from harmful particles

The first stage is the recirculation filter mat, which filters the cabin air that may be carrying infectious aerosols or other harmful particles. The mat is designed to capture larger particles and prevent them from entering the vehicle’s air conditioning system. “Focusing on larger particles at this stage prevents the recirculation filters from becoming clogged too quickly”, Beisel explained.

In the second stage, the filter in the air conditioning unit features a super-efficient filter to remove small particles from the prefiltered air. The third high-efficiency part is a separate filter in the front of the bus that simultaneously cleans the air in the driver’s cabin. This multi-stage filtration approach significantly increases the overall efficiency of bus cabin air filtration and ensures a holistic filtration concept to achieve maximum passenger protection.

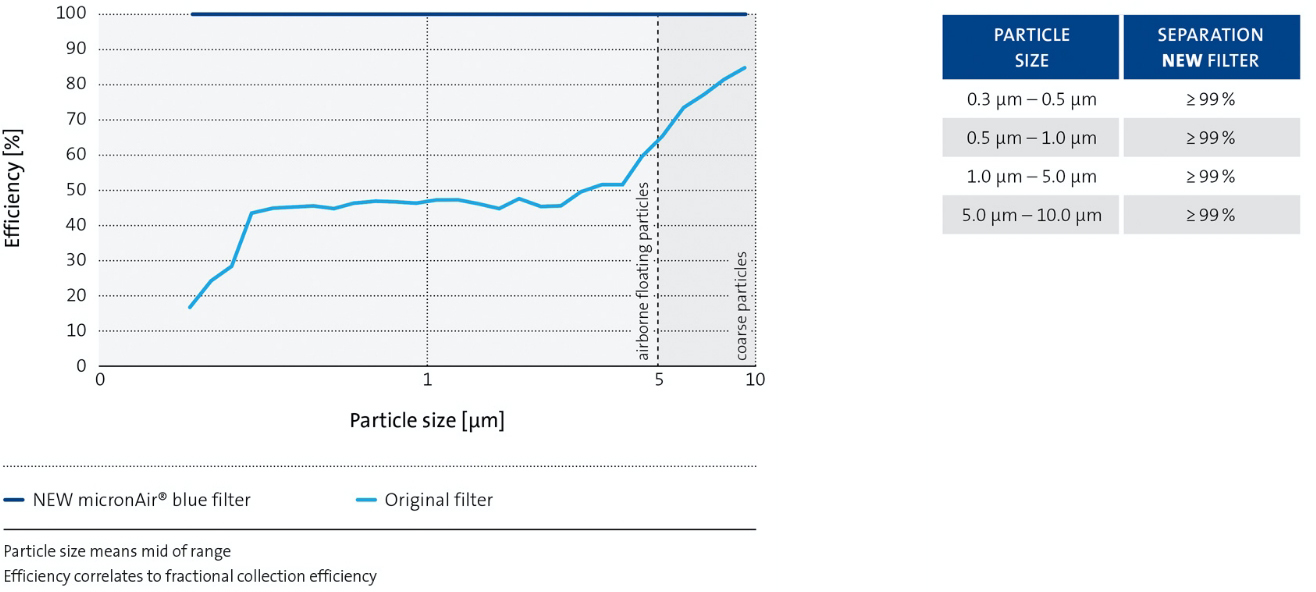

According to Beisel: “When we checked the old filters used in our test vehicles, we found they achieved roughly 50 percent efficiency for small particles of 0.4 μm. The new system ensures that almost 99 percent of all breathable fine particles are removed from the cabin air – not just aerosols, but also pollen, road dust, soot and bacteria.”

Filtration Efficiency in comparison

Viruses stand no chance

In the new three-stage system, all filters are equipped with a dual mode of action. As well as capturing particles as small as 0.4 μm, including airborne aerosols, they also feature an anti-viral filter layer based on natural fruit extracts.

When virus-containing aerosols come into contact with the fruit extract impregnated layer, the inactivation reaction leaves the viral aerosol, being collected on this functional layer, inactivated. With buses typically carrying large numbers of people, all of course breathing and releasing aerosols into the recirculating air, the ability to inactivate viruses in this way makes a major contribution to safer bus travel.

Instant success

After successfully passing a series of rigorous tests conducted by the independent Austrian research institute OFI and receiving official approval from the OEM EvoBus, the new bus cabin filters entered serial production this September. Thousands of buses in service are now being retrofitted with the new filters. New buses will be equipped with this solution as well. From next year, all newly produced EvoBus buses will have the new micronAir blue bus cabin filters installed as standard.

Freudenberg’s philosophy of innovating together has yielded a significant advance in mass-transport safety that will be enjoyed by millions of people across the globe – long past the time when this current crisis has become a distant memory.

automotive filtration insight

automotive filtration insight