Staying safe in the field

Cabin air filters in agricultural vehicles play a vital role in protecting operators against all sorts of potential hazards.

During our recent participation at EIMA International 2021 in Bologna, Italy, we were able to explain in depth and use live demonstrations to show how Freudenberg filters provide outstanding levels of protection in even the most challenging environments.

The event took place in

October 2021 at the BolognaFiere exhibition center

and was considered a great success.

That was certainly our experience, as Giacomo Menzio, responsible for the agricultural filter product and service portfolio at Freudenberg Filtration Technologies, explained:

“We were pleased to exhibit at this year’s EIMA in Bologna, which provided an ideal stage on which to present our solutions and engage in dialogue with experts and customers from around the globe. It was good to be able to participate and share our contribution to a critical subject in terms of greater operator safety, both on an equipment and educational level.”

Meeting the latest regulations

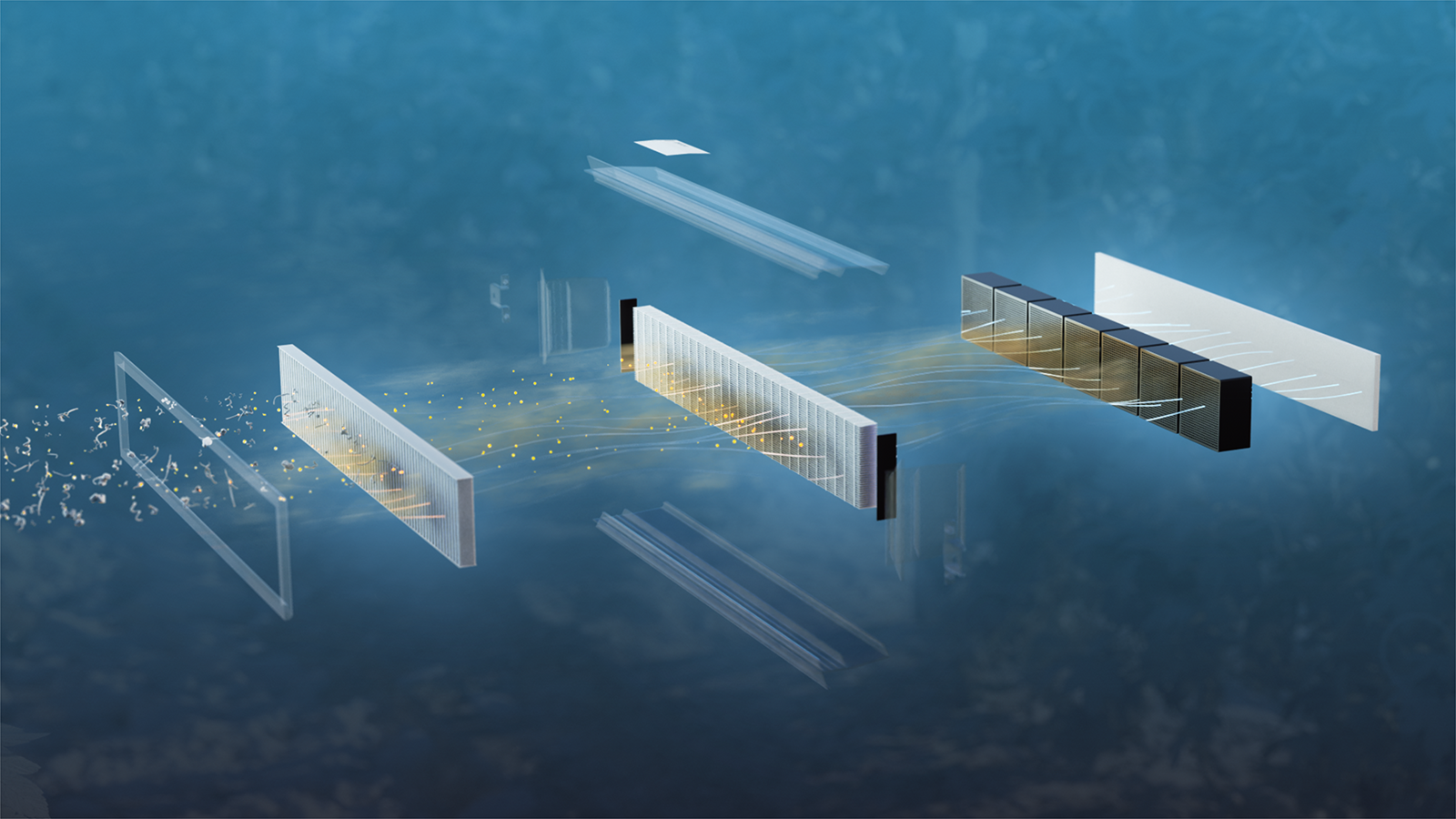

With our micronAir filters for agricultural cabin vehicle categories 2, 3 and 4, we aim to increase operator safety and well-being with products that fulfil the latest EU regulations. Since the EN 15695 standard came into force, we now have a consistent structure for identifying and addressing cabin air filtration as a cornerstone of operator safety.

The recent standard defines four cabin categories, each with different filtration requirements. Needless to say, Freudenberg can meet all of them.

“Our range of micronAir cabin air filters effectively protect operators from dust, aerosols, gases and vapors, protecting their health during spraying operations in particular”, Giacomo Menzio commented.

Multi-stage systems are the secret

As well as showcasing our individual solutions in Bologna, we offered visitors a series of live demonstrations and expert presentations by Maik Sieh, Manager Application Engineering Special Applications at Freudenberg.

Anyone who was unable to attend the event in person could instead watch a live broadcast of the presentation on EIMA’s website.

Quality is everything

To ensure reliable protection inside Category 2, 3 or 4 cabins, we strongly recommend using only high-quality OE products.

These will not only perform more efficiently and protect the operator’s health more effectively. They will also have a longer working life, ensuring less frequent service intervals and a higher dust holding capacity compared to low-quality products.

Here is a quick overview of the

five key features

to look out for:

Correct labelling

The label on the product packaging should clearly indicate the scope of use and the filter category according EN 15695-2.

Perfect fit

When a filter fits perfectly, there will be no gaps around the edges and it will sit snugly inside the roof frame. There should be no possibility that the filter could move around, even when the tractor is bouncing over rough terrain.

No damage to the seal or housing

Check to see that the seal is intact without any apparent damage or porous spots. While you are doing this, you can visually inspect the filter housing for signs of damage.

Everything should stay in place

After the first few hours of work following filter installation, take a look and see whether anything has come loose or even if there are parts missing. If this is the case, it is a clear sign that you have a substandard product.

Pleat spacing

Before you install your filter, take a good look inside. If you can see that the pleats are evenly spaced and appear uniform and stable, this is a good sign that you have a high-quality product.

automotive filtration insight

automotive filtration insight