How to spot a good agricultural filter

A few simple checks make all the difference in protecting the health of agricultural vehicle operators

Tilling and maintaining fields and other agricultural areas places a burden on the health of workers. Fine dust is stirred up, liquid manure is spread, and pesticides are sprayed. This causes the concentration of airborne chemicals, dust particles, and potentially harmful aerosols in the air to quickly rise to alarming levels. A high-performance filter in the driver's cabin is the ideal way to minimize the exposure of agricultural machinery operators to this air (and with it reduce the risk to their health).

Regardless of the specified standard, in the end it is the quality of the filter used that determines the cabin air quality and consequently the actual protection. It therefore makes sense to pay attention to a few things when buying and installing a cabin air filter to ensure the filtration effect.

Legal framework

The EN 15695 standard provides a basis for protecting the health of drivers in the European Union. It defines four cabin categories, each with different safety requirements for air filtration. Category 1 offers little protection against dust, aerosols, and vapors, while Category 4 defines comprehensive filter systems with high protection as well as effective personal protective equipment.

5 ways to recognize high-quality filters:

Correct labeling

The product packaging and filter housing should clearly indicate both the application area and the filter category according to EN 15695-2.

Perfect fit

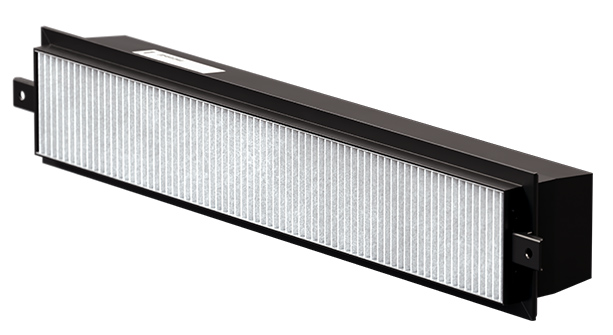

The filter should fit into the frame provided exactly. This ensures that the filter does not slip as a result of vibrations during operation and that no gaps form through which air can enter inside the vehicle unfiltered.

Undamaged gaskets and filter housing

Filter gaskets should not display any obvious damage or porous spots. The housing should also be inspected for defects before installation to ensure that leaks do not compromise safety.

Homogeneous pleat spacing

Before installation, the pleat spacing of the visible nonwoven particle layer should be uniform and the filter should give a homogeneous, stable impression.

No abnormalities shortly after commissioning

The installed filter should be re-inspected after the first few hours of operation. If everything is still in place and nothing has come loose, the filter is of high quality.

automotive filtration insight

automotive filtration insight