Looking back on 30 years of micronAir cabin air filters

A star is born

It is hard to believe there was ever a time before cabin air filters. This vital component has long since become an intrinsic part of virtually every vehicle on the world’s roads. Today, it provides better protection for passengers against particulate matter, allergens and harmful gases than ever before. What’s not hard to believe is that Freudenberg’s Innovation co-pioneered this necessary automotive component.

A very early idea for a cabin air filter came from former CEO Hans Freudenberg’s chauffeur in the 1950s. He noticed how his clothing became soiled by the polluted air entering the vehicle. He instinctively came up with the idea of placing a piece of nonwoven fabric over the air intake vents. Freudenberg’s first filter solution to address polluted air was Viledon filter mats, which launched onto the market in 1957. The filter media created formed the basis for the development of the cabin air filter.

A determined team with a clear goal

“By the 1980s, Freudenberg was already heavily involved in automotive filters. But at that point, the applications were exclusively concentrated on the engine”, states Dr Heinz Reinhardt Head of Application Engineering back at the time. “It was Freudenberg’s fundamental mission to improve human health and wellbeing that inspired the shift in focus from the engine to the people inside the vehicle.” So a young and ambitious team were given the task of exploring possible ways of incorporating air filtration into the interior ventilation system.

Now retired, Armin Tritsch, who led the initial sales drive, recalls the early days: “We really started from nothing. We had no market, no specifications to work with, no experience with the product, no internal organization and no way of manufacturing the actual filter units.” But the team did have a very clear idea of how the cabin air filter would work and what its value would be to the automotive market, and to vehicle users in particular. They also had an ambitious young engineer at Daimler, who saw the potential too.

From launch to exponential growth

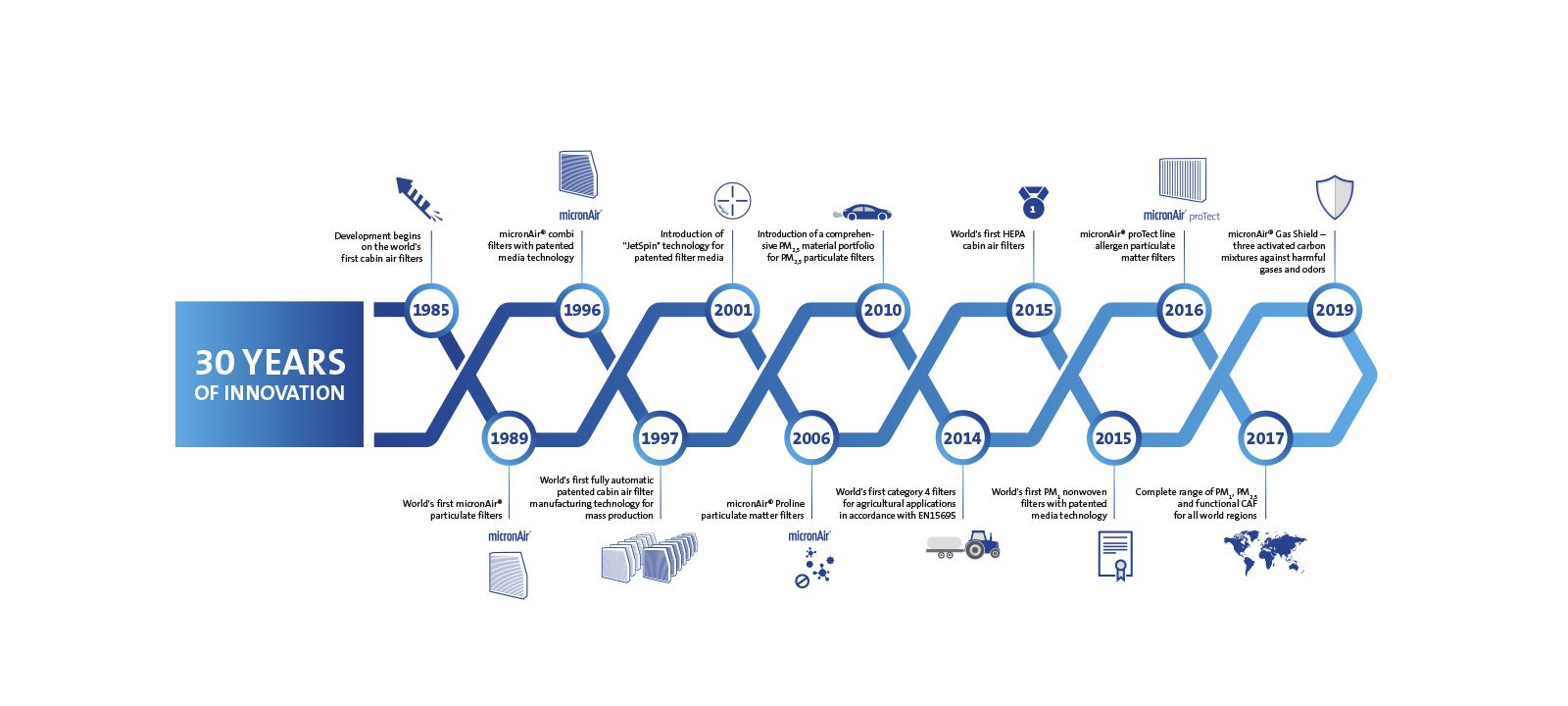

The partnership with Daimler was the turning point. The German car manufacturing giant made the decision to include the experimental new cabin air filter as standard equipment on their iconic SL roadster, in time for the launch of the latest variant in 1989. That model became the world’s first production car to feature a cabin air filter as standard equipment. Other manufacturers were quick to follow.

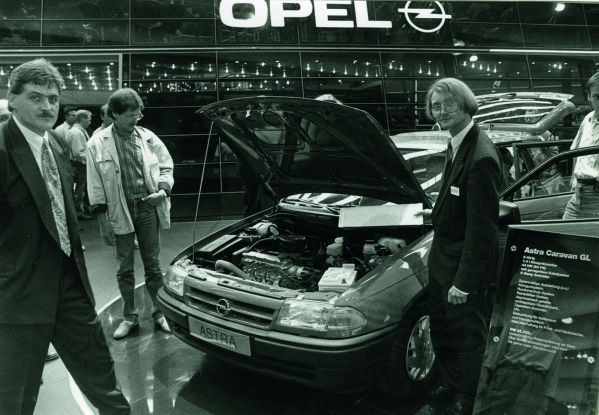

Within weeks, Freudenberg received similar contracts from VW and Audi, albeit as special equipment. But the new cabin air filter really cemented its place within the industry in 1991 with the launch of the Opel Astra. This was the first mass-market car to include the new micronAir cabin air filter as standard. And with that development, an entire new industry segment was born.

Valuable health protection for vehicle occupants

Armin Tritsch looks back on that moment with a clear sense of pride and achievement: “After the concept had been proved by Mercedes-Benz and at VW and others on a smaller scale, series specification on the affordable Astra marked the breakthrough for us. We knew then that the tremendous health benefits offered by this revolutionary product really were going to be something everyone could access.” The speed at which the innovation developed was astonishing. In 1989, Freudenberg produced 35,000 of its new micronAir cabin air filters. By 1993, the company was supplying 3.6 million units a year.

High-intensity innovation

Winning the Mercedes-Benz contract kicked-started a period of intense progression. To meet the planned production schedules for the new SL, Freudenberg had to gear up from zero to series production in just six months. Back in 1989, Volker Bräunling was part of this ambitious and talented young development team. Today, he is Regional Director Europe: “The fact that we were able to meet such a very tight deadline at all was down to our innovation capacity, ability and willingness to learn, and the fact that Freudenberg has always been prepared to take risks and invest in new ideas.”

Once the cabin air filter concept secured a firm commercial footing, the innovations followed quickly. By 1993, the micronAir development team began work on the activated carbon filter that formed the basis of today’s most advanced combi-filters. In 1995, the particulate cabin air filter was made more effective by the use of a pleated filter medium. This offered superior protection against pollen and dust particles. In the same year, the combi-filter was introduced and became standard equipment in multiple VW vehicles from 1997 onwards. It used a combination of activated carbon and particle filter layers to provide protection against both gases and unpleasant odors.

The importance of partnership

Throughout this time, in close partnership with automotive manufacturers and air-conditioning system manufacturers, Freudenberg was actively creating a constant stream of customized cabin air filters for specific models. That intense collaboration still remains a cornerstone of our business to this day. 2016 saw the launch of the micronAir proTect line of cabin air filters. These filters are capable of filtering tiniest allergens and particles to provide outstanding protection for allergy and other pulmonary condition sufferers. Our very latest innovation is the micronAir Gas Shield cabin air filter. Launched at the start of 2019, this revolutionary component provides vital protection against many harmful pollutant gases that fills the air we breathe, from nitrogen and sulfur dioxides to ammonia, ozone and aldehydes.

Keep communicating, keep sharing

Looking back on 30 years of constant innovation, it is clear that communication between Freudenberg, the automotive industry, research institutes, regulatory bodies and public interest groups has been a powerful driving force. Throughout the history of micronAir cabin air filters, there has been a constant exchange of ideas. The advancements and potential of the cabin air filter, the public’s awareness and desire for increased protection, and the necessary innovative expertise intensifies the boundaries and Freudenberg’s commitment even further.

In the early 1990s, Armin Tritsch was quick to recognize the importance of strategic communication in expanding and shaping the market for automotive cabin air filters: “The engineers, sales and marketing people all worked very closely together. We knew it was up to us to explain what the new cabin air filters could achieve and how they would protect people all over the world, adding value to our customers’ products.” Volker Bräunling agrees: “Proactive communication has been a key success factor. Today, with the revolutionary possibilities that are opening up in new forms of mobility, staying close to our customers and maintaining that dialogue is more important than ever.”

Born in 1989 and celebrating its 30th anniversary this year, the micronAir cabin air filter established an entirely new sector within the automotive industry. As we stand on the verge of the new mobility revolution, these vital components – and the Freudenberg expertise, experience and innovation spirit that power their development – are already beginning to define the next breakthrough in driver and passenger comfort, health and safety.

automotive filtration insight

automotive filtration insight