A unique innovation partnership

Testing the next generation of cabin air filters

Developing innovative filter media is one thing: gaining deep insights into their effectiveness is something else. When it comes to testing the latest filter solutions for their ability to neutralize allergens and germs, Freudenberg Filtration Technologies turns to the OFI in Vienna, Austria.

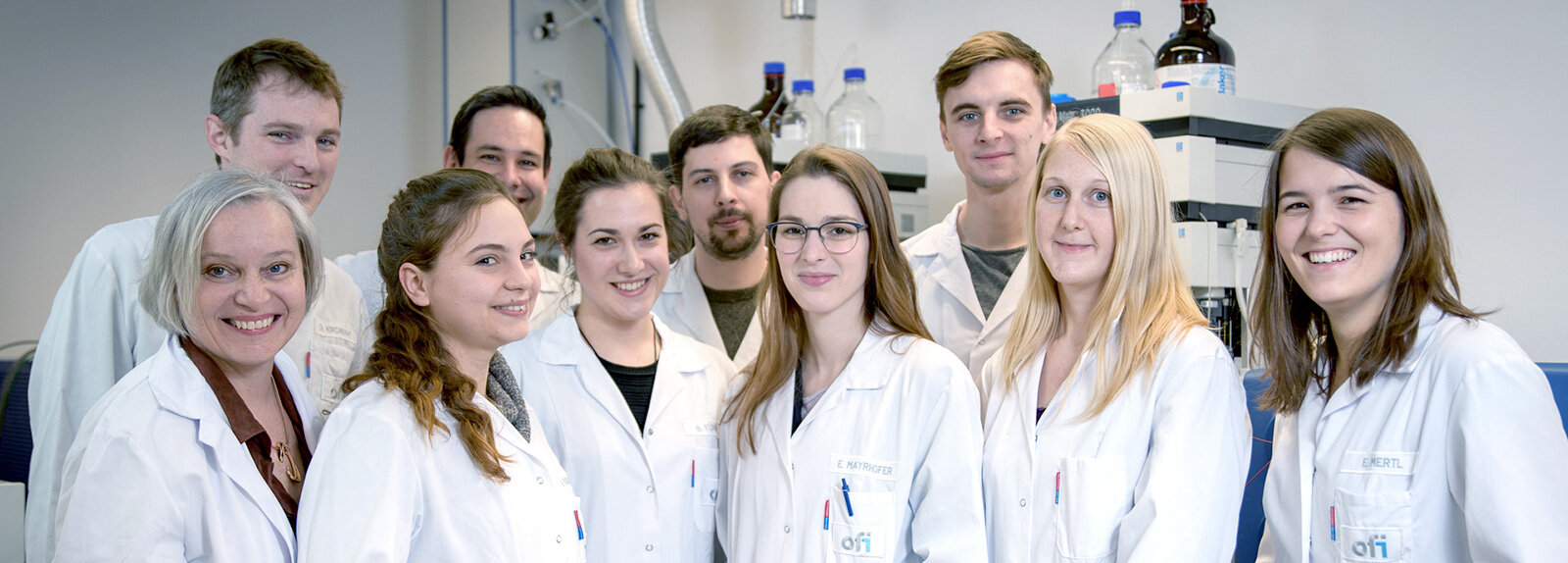

As a world leader in materials technology testing, OFI has unique facilities and expertise in testing for the effects of Class 2 substances such as allergens, germs, bacteria and viruses. In fact, when we as filtration experts were searching for a materials testing partner, the institute proved to be the only provider capable of testing filter media for these substances.

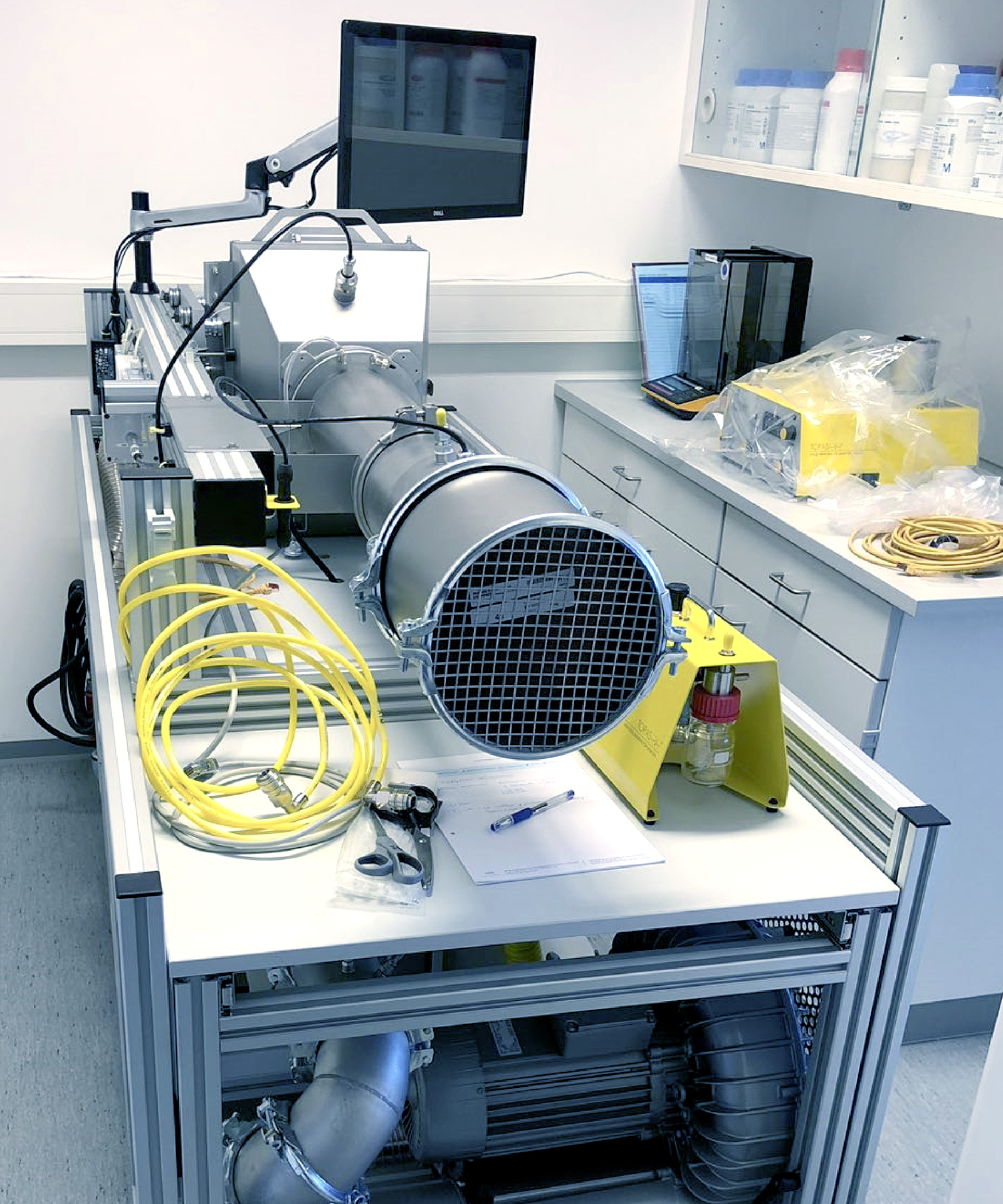

Closed circuit testing

Particularly interesting to Freudenberg’s materials engineers was OFI’s ability to test using a closed circuit. Under the project name “BOREAS”, a unique rig was designed and built to test the effectiveness of the activated carbon layer in the latest micronAir proTect line of cabin air filters. As Uwe Häfner, Head of Industrialization and Innovation Automotive Filters at Freudenberg explained: “OFI has the expertise we needed to confirm the effectiveness of filter solutions and enables us to guarantee the health benefits it offers in compliance with hygiene requirements for air-conditioning systems defined in guidelines like VDI 6032.”

Proven protection against allergens

The closed circuit test rig enabled OFI to replicate the quality of indoor and outdoor air in a way that was as true to life as possible. The team was even able to simulate the effect of the tested filter systems on the biocompatibility regarding skin and eyes. This broad testing spectrum was vital in being able to generate meaningful results that accurately reflected the function of the filter under normal operating conditions. Engineer Gabriele Ettenberger-Bornberg is a hygiene expert and project manager at OFI. “We deal in great detail with the interaction of surfaces and materials and with the evaluation of the effectiveness of filter systems. In terms of our work with Freudenberg Filtration Technologies on the micronAir proTect line of cabin air filters, we were able to prove the effectiveness of their innovative product.”

Image source: OFI/Michael Pyerin

Health protection is the motivator

The major driver of filter innovation is increasing public awareness of the dangers of exposure to air pollution. In this respect, Gabriele Ettenberger-Bornberg is uncompromising: “We see an opportunity for the automotive industry to position itself more ecologically and innovatively if it concentrates more on passenger health protection in the cabin. That is why we are so happy to be collaborating with Freudenberg, because that is their priority too.” Freudenberg Filtration Technologies and the OFI have been partners since 2013 and there is a continuous flow of projects and results between the two organizations. As Uwe Häfner observed: “We aim to develop sustainable filtration solutions that make an active contribution to human wellbeing, and the OFI is ideally positioned to help us achieve those goals. It’s an extremely productive partnership.”

Pushing the limits for the future

According to Gabriele Ettenberger-Bornberg, knowing that they are working on meaningful projects with long-term value for society is an important motivator for her young and expert team. They are proud of the work they do and the positive contribution they make.

At the same time, OFI’s expertise is a key component in Freudenberg’s ability to keep innovating filter technology to stay ahead of environmental challenges and keep protecting people. This outstanding record of collaboration gives a new and vital meaning to “INNOVATING TOGETHER”.

automotive filtration insight

automotive filtration insight