Spraying season

Keeping farmers safe during spraying season

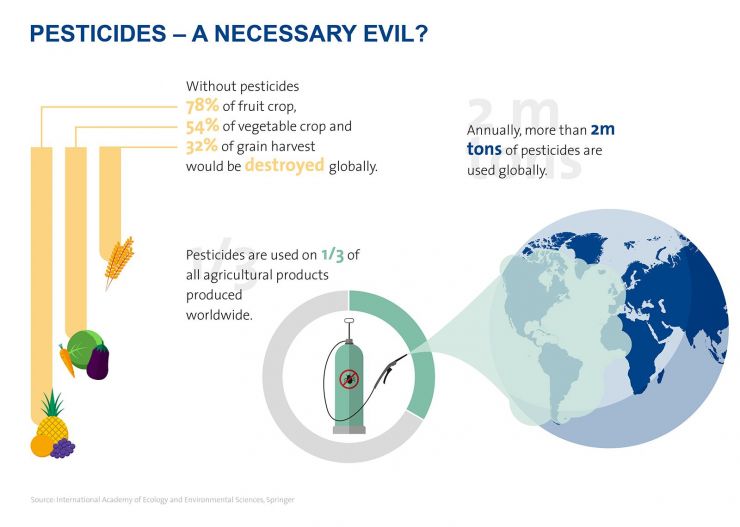

Beginning in spring and running through the summer, the spraying season is the time of year when farmers work to protect their crops from weeds, insects, fungi and diseases. The nature of the work – involving potentially toxic pesticides and liquid fertilizers – is necessary for the industry, but in turn creates a vital need to protect vehicle operators. We look at some of the key issues to bear in mind.

The spraying process routinely surrounds the operator’s cabin with dust, gases, aerosols, vapors and solid residues of the substances being sprayed. Keeping these safely outside the cabin is critical for operator health and safety. To specifically address this need, Freudenberg Filtration Technologies has developed a range of cabin air filters to ensure that effective protection can be provided according to the criteria of the European EN 15695 standard for all categories. When applying pesticides, it is essential to use Category 4 filters, which offer the highest level of protection.

Safety inside the cabin

The European EN 15695 standard was designed to specify an adequate level of air purity and the cabins and filters required to achieve it. Although more environmentally friendly alternatives are being developed, there is currently no widespread viable option to the harmful plant protection products (PPPs) and liquid fertilizers commonly used today. As a result, operator protection is a must.

To provide reliable protection, EN 15695 sets out clear guidelines for any given application. It defines four separate categories, with Category 4 offering the highest level of protection. “We recommend that farmers and operators themselves check to see if they are sufficiently protected with their current cabin air filtration solution”, explained Giacomo Menzio, who is the Global Market Manager for the agricultural filter product and service portfolio at Freudenberg Filtration Technologies.

Taking account of field conditions

There are certain driver maneuvers and external conditions that increases the cabin’s exposure to higher concentrations of pesticide “fog”. For instance, when making headland turns or slowing down. Windy days can present an additional problem, when the vehicle is vulnerable to becoming engulfed in a cloud of pesticide.

“Only a high-quality Category 4 filter can provide reliable operator protection in such high-risk situations”, Menzio continued.

“However, it needs to be installed in a properly certified Category 4 vehicle cabin.”

Reliable protection from dust, gases, aerosols and vapors

Freudenberg’s premium micronAir Category 4 filter is designed with a coordinated multi-stage filter system, which adds a unique, high-performance, activated-carbon section in the final filter stage. These highly efficient filters offer excellent protection from dusts and aerosols. They can even block vaporous contaminants that could be extremely harmful to the operator’s health. These advanced filters are now fitted as original standard equipment by the leading agricultural vehicle manufacturers.

“The filters have been on the market for some time. However, the quality and condition of these filters must be carefully and regularly checked to truly protect the operator inside the cabin from external hazards”, Menzio commented.

Using the right equipment

In Europe, all new machines are now designed to comply with the requirements of EN 15695. To achieve homologation (approval), they have to fulfill both the cabin requirements (EN 15695-1) and cabin air filter requirements (EN 15695-2). During maintenance and replacement, it is essential to check the cabin air filter’s performance, quality and certification. Optimal air quality inside the cabin can only be achieved by using original parts and checking the machine’s instruction manual to verify that the category of the cabin and filter both match.

Freudenberg’s micronAir cabin air filters are tested in accordance with EN 15695 by certified external institutes. Once design, development and performance testing have been completed, the filter initially undergoes the vehicle manufacturer’s internal approval process before going forward for formal approval according to EN 15695. Finally, depending on the intended filter application, the appropriate category is indicated on the filter label.

Regular maintenance and retrofitting

Newer vehicles have a warning light on the dashboard display to indicate when the Category 4 filter needs to be replaced. Filter replacements should always be carried out according to the recommendations in the machine’s instruction manual, and the actual hours of operation should be checked. Generally, filter replacement is recommended at least once a year, usually at the start of the new spraying season.

In principle, any agricultural vehicle cabin can be equipped with the necessary filter and ventilation system. However, because adequate protection can only be ensured with a closed cabin, we recommend upgrading older models with a heating, ventilation and air conditioning (HVAC) system for additional protection and comfort. Both the cabin and filter components need to meet the performance requirements of EN 15695. “Safeguarding operators’ health at their workplace isn’t optional – which is why properly labeled, high-performance filtration and air purification systems are an absolute must, especially at this time of the year”, Menzio concluded.

automotive filtration insight

automotive filtration insight