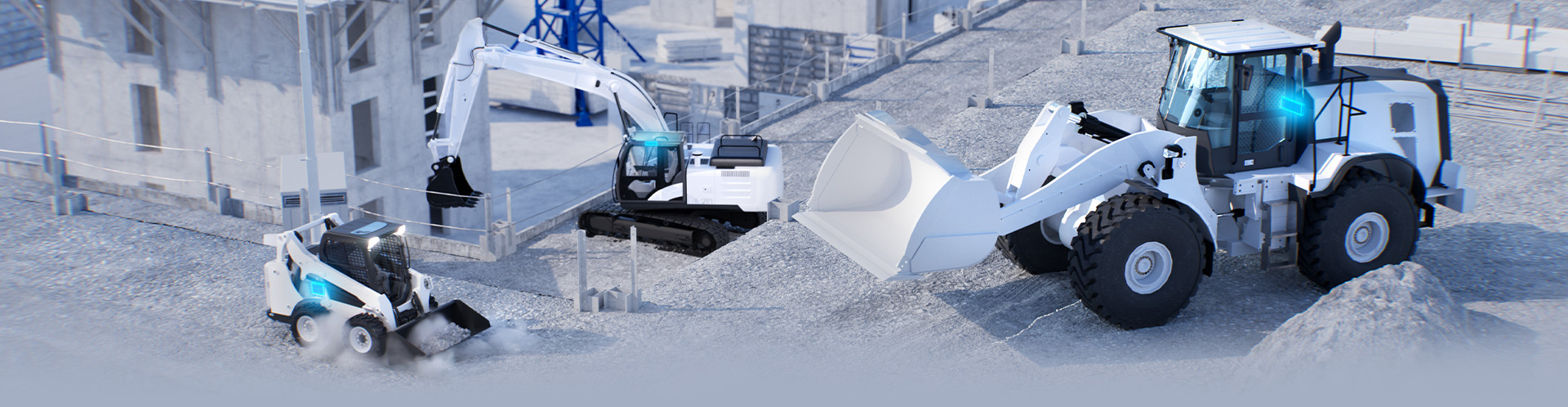

High protection in extreme conditions

Purified cabin air is essential for construction vehicles

Construction sites are constantly dusty and noisy. It is no wonder that construction site workers are in a high health risk category. Tailored filter systems for driver's cabins in construction vehicles minimize health hazards for drivers and increase safety.

Just by walking past a construction site you can often notice that the

air quality

is poor

There are a wide variety of people drilling, cutting, shredding, and milling. Such activities release dust and fibers into the air, where they can remain for a long time. Construction machinery and vehicles also emit exhaust fumes and stir up soil particles, adding to air pollution. This results in workers inhaling a wide range of pollutants and particles directly.

Fine dust:

Fine dust including silica dust, wood dust, and cement dust, can be stirred up during earthworks, demolition work, and transportation of materials.

Coarse dust:

Large particles can be stirred up by moving vehicles and machinery.

Muddy dust:

Digging, excavating, moving vehicles and handling materials can churn up mud and create fine wet particles in the air.

Chemical vapors and volatile organic compounds (VOCs):

Building materials, paints, varnishes, adhesives, and solvents can contain a wide variety of harmful VOCs or evaporate certain chemical compounds.

Diesel exhaust gases and combustion by-products:

Diesel-powered vehicles and machines as well as welding or cutting work emit pollutants such as nitrogen oxides, carbon monoxide, sulfur oxides, and particulate matter.

A workplace with increased health risks

Some substances that are frequently found in the air on construction sites can pose a long-term risk to operators' health, even in small quantities. Depending on the specific contaminants in the air, the direct consequences of exposure can include irritation of the mucous membranes and respiratory tract, headaches, dry coughing, and shortness of breath. The long-term health risks mainly affect the heart and lung function. The most concerning is the increased risk of developing cardiac arrhythmias or lung cancer or other types of cancer.

Protection against airborne pollutants is therefore essential for the health of workers.

Charting safety – Innovative construction vehicle air filtration

Even if driver’s cabins in construction vehicles appear to be protected at first glance, airborne pollutants and fine particles can accumulate in the cabin and create a working environment that causes permanent damage to health. Standard surface-loading paper filters do not provide adequate protection in most situations. At Freudenberg, we contribute superior technological and innovative air quality solutions.

Giacomo Menzio, who is responsible for the Off Highway Vehicle segment and service portfolio at Freudenberg Filtration Technologies, emphasizes.

Compared to the paper-based filter elements, the overall filtration properties of nonwoven media are also considerably better. That is why high-quality filter systems have a genuine effect on reducing the airborne load. They ensure clean cabin air and effectively protect operators from harmful particles, dust, and gases, when combined with properly designed activated carbon filtration stages. It is extremely important that cabin air quality is not compromised, as safety in the workplace is a must!

Tailored solutions

for optimal results

Freudenberg develops individual micronAir cabin air filtration solutions for any specific requirements of construction vehicles, from compact to large machines such as skid steer loaders to excavators and bulldozer.

We offer a wide range of filtration media and options, including metal and aluminum frames as well as plastic housings that are precisely tailored to the design of the particular ventilation system and the ambient conditions. In this respect, filter sealing always requires a specific technical design. The advantage of this is that the optimized filtration system not only protect the driver himself, but also sensitive ventilation components, which extends the service life of the air ventilation system and reduces maintenance cycles.

automotive filtration insight

automotive filtration insight